Pelletizer Coupling Success

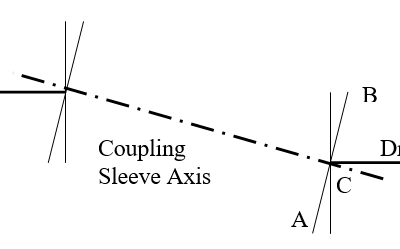

A plastics manufacturer came to CouplingCorp about 10 years ago with an interesting problem. On their plastic pelletizer machines, the cutting knives were powered by a 120 HP motor. The machine used a gear coupling to transmit torque between the motor and the knife drives. While this coupling application seems to be very simple on the surface, there was a major complication. During the process of operating the pelletizer, the knives wear down as they constantly cut plastic. The amount of this wear can vary for different size/model of the pelletizer, but it is a significant amount of movement that changes the length of the coupling as it wears. For example, when new knives are installed, the Distance Between Shaft Ends (DBSE) might be 10.75 inches (273mm). By the time the knives have worn to the point of being replaced, the DBSE could be down to 10.06 inches (255.5mm). This means the coupling must accept an axial change of 0.690 inches (17.5mm). Even for a gear coupling, this is a large amount of movement.

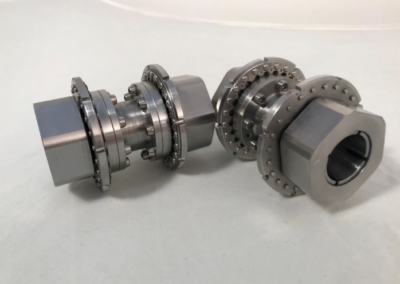

The user wondered if it was possible to replace the gear coupling with a maintenance-free, non-lubricated coupling. But, they worried about whether a flexible coupling could handle the large movement without putting too much axial force on the hydraulic knife positioning system. In other words, if the coupling was too stiff, the axial force generated by the coupling would be larger than the hydraulic force used to position the knives to cut the right size pellets.

CouplingCorp looked at the situation to determine if such a coupling could be produced. After doing an analysis of the axial forces found in the gear coupling during operation, it was determined that the FLEXXOR coupling would have a lower axial force than the original gear coupling did. The final hurdle was a large axial movement, and with the use of some high-misalignment diaphragms, the problem was solved. The coupling was designed to handle +/- 0.384 inches (9.7mm) of axial travel which is a total range of 0.768 inches (19.5mm). With this axial capacity, the user was able to stretch the coupling to accommodate the new knife position, and then gradually the coupling would move through the neutral position to a compressed position as the knives wore down to their lower limit.

The user installed a first coupling, and it worked as predicted. After a trial phase, the same coupling was implemented on all pelletizers at the plant. The coupling has been running successfully for many years without any maintenance.

Contact Us Today

"*" indicates required fields

Recent Posts

Lady and the Clamp

Why Machine Alignment Matters

Vibration Transmission in Couplings

I Like Big Hubs (and I cannot lie)

Circ Water Success

Surprise BSE Change

How CCA Saved a Customer Millions

FLEXXOR Coupling Reduces Vibrations in Gas Compression Application

New Year’s Resolution: Coupling Weight Loss

Downtime – Way Up in the Sky