FLEXXOR Coupling Reduces Vibrations in Gas Compression Application

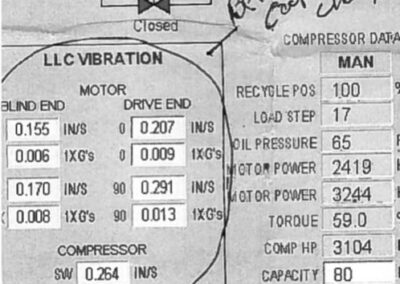

For several years a gas gathering company dealt with high vibrations on the motor driving a 6 throw, 5400 HP reciprocating compressor. Over that time, they made several attempts to reduce the levels, but none were successful. On the output end of the motor, the vibrations amounted to 0.291 inches per second (7.39 mm per second). In this case, torsional excitations did not appear to be a problem. The company wondered if there was a simple way to reduce vibration in reciprocating compressors.

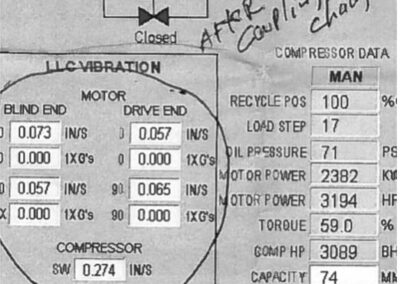

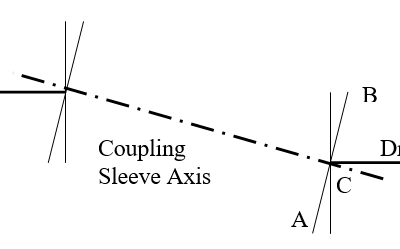

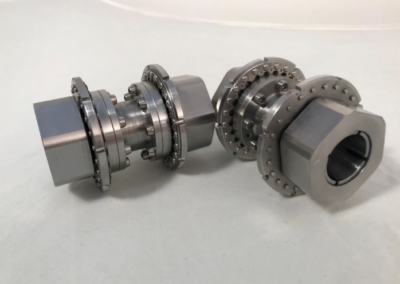

The engineers involved decided to look at the bending stiffness of the coupling. The existing coupling was a typical disc-style, but it was relatively stiff in the axial and angular (bending) orientations. They decided to try the FLEXXOR coupling, which was a more forgiving coupling style. The difference between the original disc coupling angular spring rate and the FLEXXOR is approximately 10 times lower.

Immediately after installing the FLEXXOR coupling, the vibrations on the motor output end dropped to 0.065 inches per second (1.65 mm per second) which is over 4 times lower. See the before and after vibration data sheets below. These were the lowest levels ever recorded on that particular unit. Since then, the system maintained the low vibrations through all ranges of operation.

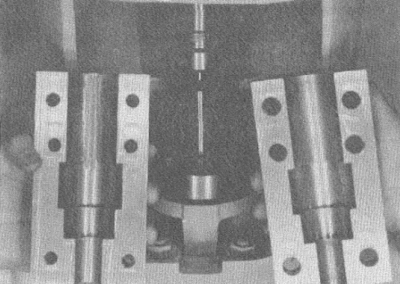

The installation was also performed very quickly using the Anderson Clamp Hub which eliminated the need for any heat or hydraulics. This keyless hub also eliminates the need for shims to help with axial positioning of the equipment. The hub can easily be set and then reset to handle any changes in the equipment spacing. After 6 years of running, this application is still operating with no problems.

Over the longer term the reduced vibrations and bending moments should also help enhance the life of the bearings and seals. The company continues to use the FLEXXOR coupling as a way to reduce vibration in reciprocating compressors and help their various equipment continue to run reliably.

Contact Us Today

"*" indicates required fields

Recent Posts

Lady and the Clamp

Why Machine Alignment Matters

Vibration Transmission in Couplings

I Like Big Hubs (and I cannot lie)

Circ Water Success

Surprise BSE Change

How CCA Saved a Customer Millions

FLEXXOR Coupling Reduces Vibrations in Gas Compression Application

New Year’s Resolution: Coupling Weight Loss

Downtime – Way Up in the Sky