Nuclear power

Home » Industries »

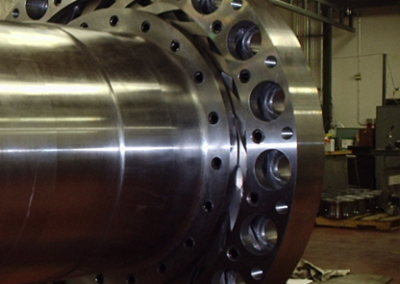

Dependable Couplings for The Nuclear Power Industry

Coupling Corporation’s flexible couplings and Anderson Clamp Hubs meet the Nuclear Power Industry’s need for reliability, dependability and maintenance free performance. Our numerous nuclear installations continue to perform flawlessly year after year. Although CCA does not have an official 10 CFR 50 Appendix B program, our quality program is designed to that standard. Therefore, it is very easy for our customers to perform Commercial Grade Dedication on our products to use them in Safety Related applications.

As plant budgets are under continual pressure, reduction of manpower is a constant concern. For many plants, the gear couplings that were part of the original design require a large amount of manpower for preventative maintenance for things like greasing and wear checks. Unfortunately, as those tasks are cut from the schedule, the equipment runs the risk of unexpected failure. This is why switching to non-maintenance CCA couplings makes perfect sense. It eliminates the manpower needed to perform PM’s and it makes installation and removal quicker during outages.

CCA Products for Nuclear Application

Many CCA products are currently in use throughout the world in Nuclear applications. Popular products include:

- Anti-Reverse Couplings

- Close Coupled Couplings

- Flexible Shaft Couplings

- Keyless Hubs

- Solid Shaft Rigid Couplings

- Torque Limiting Couplings

- Vertical Clamp Couplings

Applications include high misalignment areas and high thermal growth equipment.

Popular applications include:

- Compressors

- Fly Wheels

- Gas Turbines

- Gear Box

- Pumps

Applications Where CCA Couplings Are Being Used in The Nuclear Industry:

- Feedwater Pump

- Circulating Water Pump

- Charging Pumps

- High Pressure Safety Injection (HPSI)

- Reactor Coolant Pumps (RCP)

- Turbine Makeup Pumps (TMU)

- Spent Fuel Cooling Pumps

- Containment Fan Cooler Units (CFCU)

- Auxiliary Feedwater Pumps

- Low Pressure Safety Injection (LPSI)

- Turbine Plant Cooling Water (TPCW)

- Residual Heat Removal Pump (RHR)

- Reactor Coolant Safety Injection (RCSI)

- Condensate Booster Pump

- MG Set