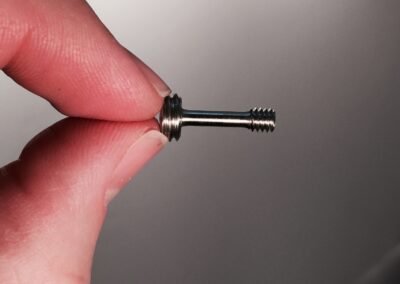

Quill Shafts

About Quill Shafts

Quill Shafts are thin, solid shaft strategically designed to carry the same torque as a larger shaft, by operating at higher stress levels. In carrying torque, the quill shaft acts like a torsional spring, twisting along its length.

Quill shafts have been used for decades in refrigeration compressors with outstanding success rates. There are several reasons for selecting the quill shaft in these applications:

- The small diameter of the quill shaft allows for the use of much smaller seals that can work at lower rubbing velocities than their larger counterparts.

- Quill shafts significantly reduce the amount of overhung weight, which reduces the vibration in the system.

- A Quill shaft is generally used in conjunction with a single hinge coupling. Because the quill shaft is capable of bending in a cantilever fashion, only a single hinge is needed to provide complete misalignment capability.

- The thin shaft torsionally isolates the high-speed compressor from forcing frequencies such as gear mesh frequencies or driver pulsations.

There are some other subtleties with the quill shaft that add to the success of these applications.

While the quill shaft has seen much success in compressor applications as a single hinge and cantilever design, other applications have benefited from the use of a quill shaft spacer between two flexible elements. The term double hinge means that the coupling accepts offset misalignment of the coupled shafts by angulations of each flexible element at the ends of the spacer.

In a torsionally soft application, the quill shaft would typically be used in a coupling with a flexible element at both ends of the shaft. The shaft does not have to bend in response to misalignment. The quill shaft reduces torsional vibrations and pulsations.

Quill Shafts Designed to Smooth Out Vibrations

The quill shaft makes it possible to minimize transmission of torsional pulsations between machines. Designed with a low enough spring rate to smooth out vibrations produced by reciprocating engines or compressors.

Some manufacturers make torsionally soft couplings using a rubber element instead of a quill shaft. There are several disadvantages to using rubber elements:

- Rubber torsional springs are heavier and much larger in diameter

- Rubber has a finite life with faster failure rates with hard use

- Rubber spring challenges achieving a high torque rating and a very low spring rate.

Example Applications

A diesel engine driving a compressor through a gearbox is an ideal application for a quill shaft. The pulsating diesel explosions can be isolated from the gearbox and compressor when utilizing a quill shaft providing a low torsional spring rate.

Synchronous motors produce high torsional pulsations during startup. A low torsional spring rate coupling can greatly reduce torsional stresses in the shafting during this critical period.